|

ANIMAL SLIDES:

<Researchers><Development><Test Data> |

|

|

|

EQUIPMENT |

|

eq1 |

|

<Previous>

<Full

size>

<Next>

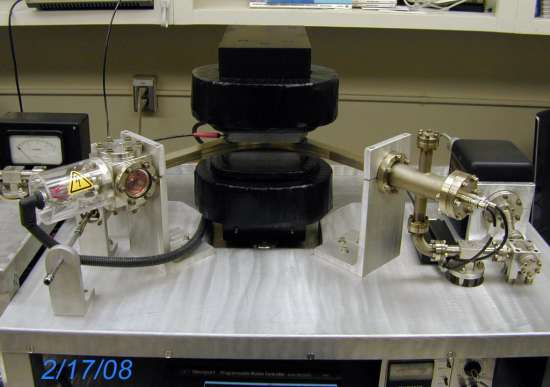

The mass spectrometer for ANIMAL is a 10-cm, 90° sector instrument with second order focusing (after Cross, 1951). The spectrometer has a single electron multiplier detector (ETP discrete dynode type), housed in a standard reducing cross (right). The source is based on a standard 2.75" cube. Note that there are two pairs of coils for the electromagnet-analyzer, and each is controlled with a 12-bit controller. The larger set of coils is kept in constant-current mode sufficient for a field of ~ 3100 Gauss (sufficient to being mass 35 to the detector, when operating at 2 kV). The smaller set of coils is under computer control, and when fully energized can increase the field to ~ 3500 Gauss (sufficient for ~ m/e=40.5 @ 2 kV). The total spectrometer volume (including an appendage getter-pump) is about 400 cc.

|

|

eq2 |

|

<Previous>

<Full

size>

<Next>

The extraction line has a volume of about 400 cc.

An air pipette (with pneumatic valves) and a turbo pump connect to

the extraction line underneath the table.

|

|

eq3 |

|

<Previous>

<Full

size>

<Next>

The operation of the laser system, extraction line, and analysis are fully automated, through a Labview program.

|

|

1 |

|

<Previous>

<Full

size>

<Next>

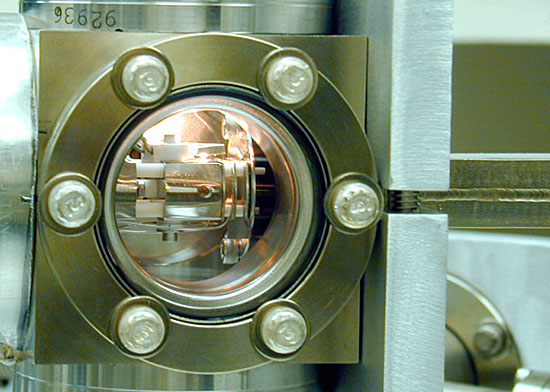

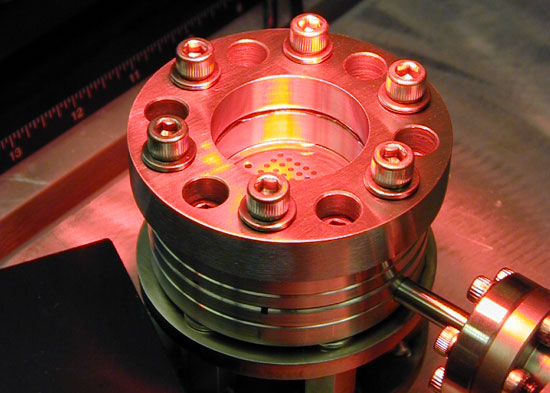

View of the Nier-type electron impact source

(after Wallington) and filament through a Pyrex window on the source

block (a standard 2.75” UHV cube). The source is spring-loaded, and

is guided with pins to rest on a plate to the right. Note the

external source magnet housings above and below the source.

|

|

2 |

|

<Previous>

<Full

size>

<Next>

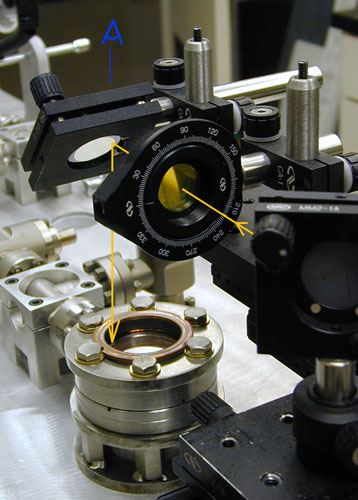

A

second view of the ion source, with the beginning of the flight tube

at the right

|

|

3 |

|

<Previous>

<Full

size>

<Next>

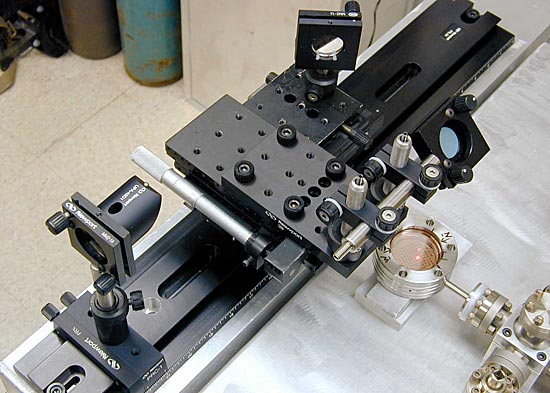

Early development and testing of the ‘flying

optic’ design for the laser sample chamber. The laser beam (from a

He-Ne steering laser in this case) comes from below the table

through a hole in the rail (to the left) and is directed down into

the sample chamber.

|

|

4 |

|

<Previous>

<Full

size>

<Next>

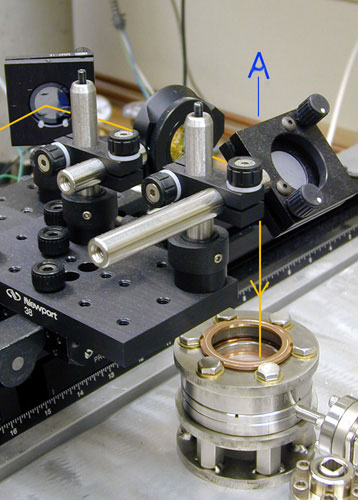

View of the optical path for the laser at a later stage of lab

development

|

|

5 |

|

<Previous>

<Full

size>

<Next>

View of the optical path for the laser at a later

stage of lab development.

|

|

6 |

|

<Previous>

<Full

size>

<Next>

Heating and sample chamber bakeout to ~ 150 C

with an IR heat lamp.

|

|

7 |

<Previous>

<Full

size>

<Next>

Heating and sample chamber bakeout to ~ 150 C

with an IR heat lamp.

|

|

8 |

|

Top of Page |